Technology

To realize zero-emission society ,

we develop cutting-edge technology with high environmental performance and contribute to low-carbon society.

In Oshima Shipbuilding, we conduct various initiatives from environmental viewpoint under corporate creed to safeguard the environment. We offer low fuel consumption and low CO2 emission ships by hull form development using circulating water tank. Moreover, to realize zero-emission society in the future, we develop cutting-edge technology with high environmental performance and apply result to our ships to contribute to low-carbon society.

Individual technologies

Wind challenger

We completed the world’s first ship equipped with Wind Challenger on October 7, 2022. Wind Challenger is a device that converts wind energy to propulsive force with telescopic sail (rigid wing sail), and with this installed on ship, reduction of environmental impact and improvement in economic efficiency are expected through reduction of fuel consumption.

The research and development first started in 2009 as industry-academia joint collaboration research project lead by the University of Tokyo, and has been jointly developed mainly by Oshima Shipbuilding and Mitsui O.S.K. Lines, Ltd. after January, 2018.

This ship is a coal carrier operated by Mitsui O.S.K. Lines, Ltd., and the effect of CO2 reduction by Wind Challenger installation is expected to be about 5% on a Japan-Australia sea route, and about 8% on Japan-North America West Coast sea route compared to conventional coal carrier of same type.

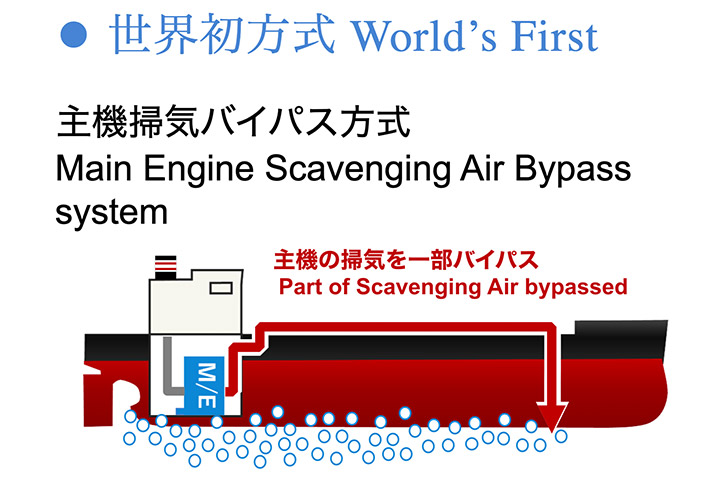

Air Lubrication system

The world’s first air lubrication technology using a main engine scavenging air bypass, a device that reduces frictional resistance on ship by creating layer of air bubble flow between seawater and ship bottom, is applied to Post Panamax bulk carrier “M/V SOYO”.

The CO2 reduction effect was confirmed to be 3 to 8%, depending on the draft of the ship.

This system is a high-efficiency air supply system that extracts the surplus of main engine’s scavenging air created by high-efficiency turbocharger, and transports it to the bottom of the ship using scavenging bypass pipe for air lubrication. In this system, the energy required for air supply to the bottom of the ship has been minimized.

“M/V SOYO” was awarded “Minister of the Environment award 2012”, “Ship of the year 2012”, “Nikkei Global Environmental Technology Award 2013” and “10th Eco products award”.

Japan’s first all-electric-battery-driven ferry boat with an autonomous ship navigation system “E/V e-Oshima”

Oshima Shipbuilding developed all-electric-battery-driven ferry boat “E/V e-Oshima” equipped with 600 kWh lithium ion batteries. While sailing, it does not have any emissions, including carbon dioxide (CO2), nitrogen oxide (NOx) and sulfur oxide (Sox), making it a zero emission vessel.

The e-Oshima is Japan’s first commercial vessel using DC (direct current) grid system, minimizing electricity conversion loss (DC-AC conversion) in the distribution from battery to propulsion motor and cabin air conditioner.

The autonomous ship navigation system is also installed on the e-Oshima, developed jointly by Oshima Shipbuilding and MHI marine engineering, Ltd. The system controls course and speed to avoid colliding with other vessel. This autonomous ship navigation has been selected as one of MLIT’s FY2018 autonomous ships demonstration projects.

The e-Oshima has realized quiet and comfortable voyage only possible with the battery-driven vessel, without any noise and vibration from engine on the vessel.

“E/V e-Oshima” was awarded “Good design award 2019” and “Kyushu Transport Bureau Director Award (Environmental Conservation Division)”.

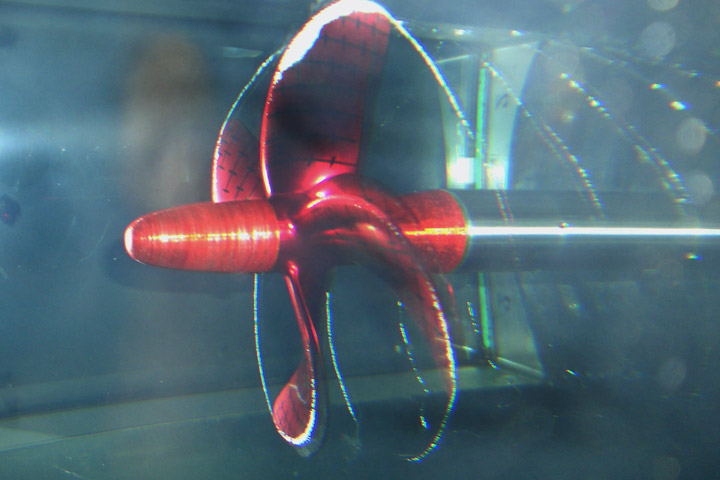

MAITA propellers

The “MAITA Propeller” is optimized for each ship with Oshima’s unique propeller design technology to maximize propulsion efficiency, and has a track record of adoption to more than 200 vessels so far.

We are conducting propeller performance tests using the in-house circulating water tank, and will continue to aim for even higher efficiency.

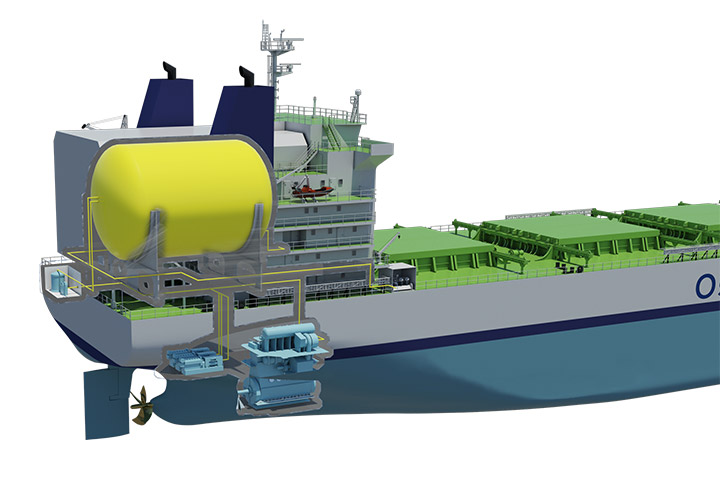

LNG fueled ship

LNG, compared to conventional heavy oil fuel, is expected to emit almost 100% less Sulfur Oxides (SOx), 80% less Nitrogen Oxides (NOx) with lean burn, and 30% less Carbon Dioxide (CO2), so it is considered to be a next generation fuel with low environmental impact. Oshima Shipbuilding is constructing LNG fueled coal carrier to be completed within FY 2023, and second and third LNG fueled coal carrier to follow are also planned.

The characteristic of this ship is a large LNG tank located on upper deck, and U shaped accommodation unit minimizes the reduction of cargo capacity caused by tank installation. This design received AiP (Approval in Principle) certificate from DNV-GL in 2015.

Ammonia fueled ship

As ammonia combustion does not emit CO2, it is attracting attention as one of next generation fuels to achieve complete zero emission. Oshima Shipyard is developing ammonia fueled ship jointly with Sumitomo Corporation, and achieved an Approval in Principle (AiP) from world’s leading classification society DNV in December 2022. We are now working together with Sumitomo Corporation, DNV and other related parties for further design optimization.